THIOSCAV Q56-68

is an advanced solution developed by the Ecoil Technologies Laboratory, specifically designed for the effective removal of hydrogen sulfide and thiol compounds from produced water and ballast water in marine vessels

Ecoil Technologies’ H₂S & Mercaptan Removal Solution for Produced and Ballast Water

Our solution is an advanced chemical treatment system developed by Ecoil Technologies Laboratory, specifically engineered to remove hydrogen sulfide (H₂S) and thiol (mercaptan) compounds from produced water in oilfield operations and ballast water aboard marine vessels.

The treatment is based on non-triazine, formaldehyde-free chemistry, offering fast reaction kinetics and high selectivity toward sulfur compounds. It is fully compatible with existing separation, injection, and discharge systems, and can be applied in batch, continuous, or in-line modes.

KEY ADVANTAGES

- High Efficiency: Rapid and permanent neutralization of H₂S and mercaptans even at low ppm levels.

- Non-Fouling Formulation: Prevents scale formation, polymerization, and equipment clogging.

- Environmentally Compliant: Biodegradable, low-toxicity chemistry designed to meet IMO and discharge water quality regulations.

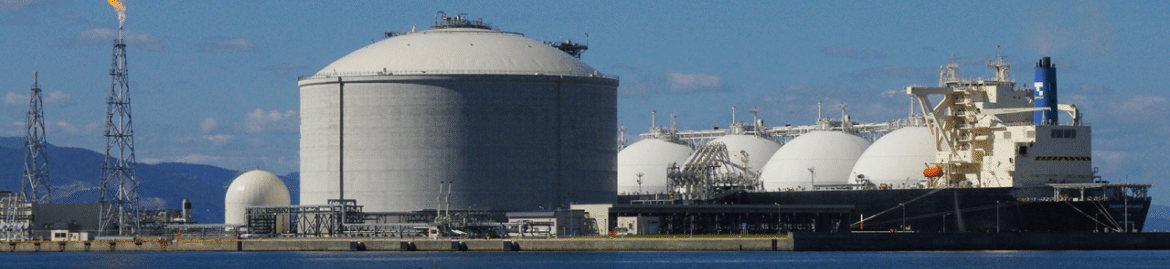

- Flexible Application: Suitable for onshore and offshore installations, FPSOs, tankers, and water treatment skids.

- Low Dosage Requirement: Lower treatment costs due to high active efficiency and targeted reactivity.

- Operational Safety: No formaldehyde, no triazine, no corrosive or hazardous by-products.

Field Use Scenarios

Produced water sweetening prior to re-injection or disposal

Ballast water conditioning to reduce sulfur content before port discharge

Compatibility with deoxygenation and biocide programs

Why Choose Ecoil’s Non-Triazine, Non-Formaldehyde Technology For water PURIFICATION?

Ecoil Technologies offers a superior alternative to conventional scavengers with clear advantages across operational, environmental, and economic metrics:

- No Solid By-products – Unlike triazine and formaldehyde-based scavengers, our solution produces no sludge, no FeS, and no polymer buildup — ensuring cleaner systems and reduced maintenance.

- Low Corrosion Risk – Our chemistry minimizes corrosion, protecting infrastructure and prolonging equipment life.

- Eco-Friendly and Compliant – Fully biodegradable and aligned with IMO, ISIRI, and global discharge regulations, ideal for both onshore and marine use.

- Higher Efficiency, Lower Dosage – Effective treatment with up to 75% less chemical consumption, translating to significant OPEX savings.

- Safe Handling – No hazardous classification, making storage and injection safer for personnel and operations.

- Broad Compatibility – Works seamlessly in produced water, ballast water, injection systems, and more, without interfering with other treatments.

RELEASED caseS

H₂S Removal from Produced Water Hydraulic Fracturing Project- Middle East

- Produced water containing 150 ppm H₂S was treated with a non-triazine Thioscav Q56-68 scavenger at a 1:3 dosage ratio.

- The treatment reduced H₂S to 0 ppm without generating solids or scale, delivering water fully compliant for use with drag-reducing agents in fracking operations.

- Result: safe, clean, and reuse-ready water with maintained viscosity and zero operational issues.

H₂S Removal from Produced and Industrial Wastewater – Central Asia

- Wastewater containing 200–1,100 ppm H₂S was treated with a non-aldehyde Thioscav Q56-68 scavenger. At an optimal dosage of 30–40 L/h, hydrogen sulfide was reduced to 0 ppm, with no formation of insoluble deposits.

- The treated water met reinjection quality standards and was compatible with other process chemicals.

- The scavenger maintained full performance in winter conditions down to -25 °C during operation (freezing point -42 °C), delivering consistent results even with reduced contact time.

H₂S Removal from Produced Water – Iraq

- Produced water with an initial 500 ppm H₂S content was treated using an efficient non-aldehyde scavenger.

- The process reduced hydrogen sulfide to below 10 ppm, ensuring compliance with injection water quality requirements.

- The treated water is now safely used for reservoir injection to maintain formation pressure, eliminating corrosion risks and improving operational safety without generating insoluble deposits.