TARGETING CASE STUDIES

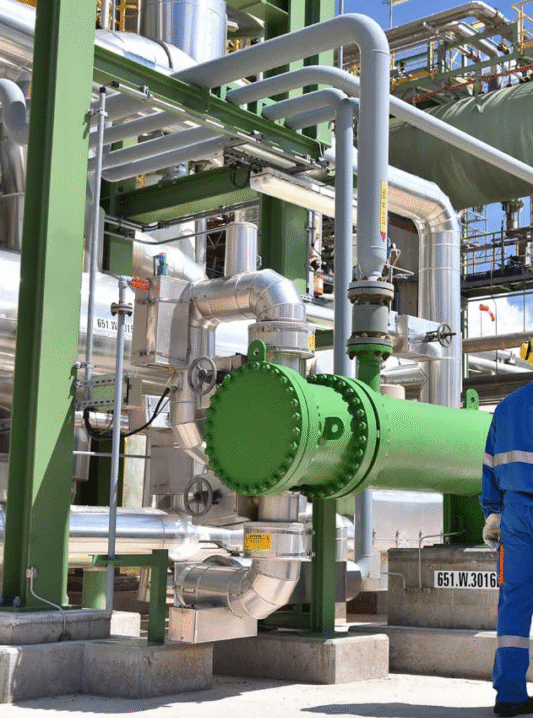

Ecoil Tech. is a specialized provider of advanced solutions and products for the removal of hydrogen sulfide (H₂S) and mercaptans across crude oil & liquids, wells products, produced water, and different types of gases.

Problems Caused by Hydrogen Sulfide (H₂S) and Mercaptans (R–SH)

Health and Safety Hazards

- H₂S is a highly toxic gas; even small concentrations can cause irritation, while higher levels can lead to unconsciousness or death.

- Mercaptans have extremely strong odors detectable at parts-per-billion levels, creating odor nuisance and discomfort for personnel and surrounding communities.

Severe Corrosion

- Both H₂S and mercaptans accelerate corrosion of carbon steel and alloys, especially in the presence of water, leading to equipment damage, sulfide stress cracking (SSC), and hydrogen-induced cracking (HIC).

Operational and Process Issues

- High sulfur levels in crude oil or gas cause off-spec products that fail to meet pipeline and export requirements.

- Sulfur compounds poison refinery catalysts, reducing process efficiency.

- In produced water, these compounds interfere with scale inhibitors, drag reducing agents (DRA), and water reinjection systems.

Environmental Impact

- Emissions of H₂S and mercaptans cause strong odors and environmental complaints.

- Oxidation forms sulfur oxides (SOₓ), contributing to acid rain and air pollution.

Economic Losses

- Reduced crude oil value due to high sulfur content.

- Increased chemical usage, maintenance costs, unplanned shutdowns, and potential environmental fines.

.

Importance of Removing Hydrogen Sulfide (H₂S) and Mercaptans (R–SH) – Compliance with International Standards

The removal of H₂S and mercaptans from crude oil, natural gas, and produced water is a critical operational and safety requirement in the oil & gas industry. These sulfur compounds present significant risks to health, equipment integrity, and product quality, and are strictly regulated by international specifications.

Health, Safety & Environmental Compliance

- H₂S is classified as a highly toxic gas by the Occupational Safety and Health Administration (OSHA) and the European Chemicals Agency (ECHA), with permissible exposure limits of only a few parts per million.

- Mercaptans, although less toxic, have strong odors that exceed World Health Organization (WHO) nuisance thresholds even at extremely low concentrations.

- Strict emission limits are enforced under US EPA and EU Industrial Emissions Directive regulations.

Product Specification Standards

- Crude oil and condensates must meet sulfur content limits defined by ASTM D5705 (H₂S in crude), ISO 6326 (H₂S in natural gas), and various pipeline company specifications (often ≤ 10–20 ppm H₂S).

- Natural gas odorization and mercaptan removal must meet AGA and ISO standards for gas quality.

- Refineries demand feedstocks free from reactive sulfur to prevent catalyst poisoning and ensure compliance with Euro 5/6 and IMO 2020 low-sulfur fuel standards.

Operational Reliability & Corrosion Control

- International guidelines such as NACE MR0175/ISO 15156 require control of H₂S in oil & gas systems to prevent sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

- Prolonged exposure of infrastructure to H₂S and mercaptans accelerates corrosion, leading to costly shutdowns and repairs.

Market and Economic Value

- Meeting global crude oil specifications (API, ASTM, ISO) ensures access to premium export markets and prevents price penalties for high-sulfur cargoes.

- Failure to control sulfur content can result in cargo rejection, demurrage costs, and regulatory fines.

Conclusion:

Effective removal of H₂S and mercaptans is not only a technical necessity but a legal and economic imperative. Producers, midstream operators, and refiners rely on proven scavenger technologies to meet stringent international standards, protect personnel and assets, and maximize the value of their hydrocarbons.

Case studies

Our case studies showcase real-world applications of our non-triazine H₂S scavenger across the oil and gas sector.

From offshore marine tankers to onshore crude oil terminals, we demonstrate how our technology delivers:

- Rapid H₂S removal – achieving pipeline specifications within minutes of contact.

- Optimized chemical consumption – reductions of 50–80% compared to conventional scavengers.

- Operational compatibility – proven performance in heavy crude, high-temperature environments, and with DRA-treated water.

- No adverse by-products – minimizing salt formation and preventing precipitation.

Each project summary includes treatment parameters, dosage rates, and achieved results, providing a transparent view of efficiency, cost savings, and operational benefits for producers, midstream operators, and traders.

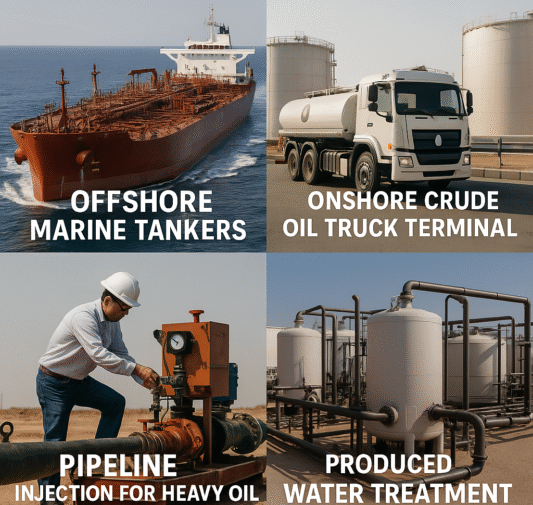

TARGETING caseS IN OIL AND GAS INDUSTRY

Eliminating H₂S and mercaptans from Crude Oil in Marine Tankers

- Thioscav Q87-05 ® cuts chemical costs by $10K/month

- 50% fewer deliveries

- Millions of barrels treated — tankers and barges consistently in spec

Crude Oil Truck Terminal H₂S Treatment

- Cut chemical spend by $35K/month using Thioscav Q87-05 ®

- 75% fewer deliveries required

- Reduce chemical usage by up to 80%

Midstream Solutions for Reliable H₂S & Mercaptan Removal

- Thioscav Q87-05® enabled the customer to reliably achieve H₂S and mercaptan specifications that prior third-party products failed to meet.

- Total treatment costs were reduced by more than 25%.

THIOLS (MERCAPTANS) TREATMENT TARGETING caseS

Thioscav Q87-05M

Mercaptan Removal from Ballast Water in Ships and Tankers

A major shipping operator deployed a non-triazine mercaptan scavenger to treat ballast water onboard vessels before discharge. The solution effectively reduced mercaptan levels to below regulatory limits, eliminating strong odors and ensuring compliance with port and environmental standards. The treatment was applied directly in ballast tanks, offering a fast, safe, and scalable approach with no need for additional onboard infrastructure.

Thioscav Q87-05M

Mercaptan Removal from Gas Condensate

An upstream operator implemented Thioscav as a non-triazine, non-amine scavenger to treat sour gas condensate with high mercaptan content. The treatment was injected directly into storage and loading lines, reducing total mercaptans to below 80 ppm and meeting export specifications. The solution eliminated the need for blending and reduced handling odors, while maintaining product quality and minimizing operational costs.

Thioscav Q87-05M

Mercaptan Reduction in Crude Oil and Gas Condensate During Marine Transport

A shipping operator applied a non-triazine scavenger onboard oil tankers to reduce mercaptan levels from 5,000 ppm to meet export specifications. The treatment was injected in-tank during transit, achieving compliant sulfur content by arrival without blending. This ensured odor control, regulatory compliance, and uninterrupted offloading at destination terminals.

TARGETING caseS IN Landfill and Organic Waste Gas Processing

Case 1: Landfill Gas H₂S Removal for Power Generation

- Location: Municipal landfill, Eastern Europe

- Problem: H₂S levels exceeding 3,500 ppm, causing severe corrosion in gas engines.

- Solution: Installed non-triazine scavenger dosing with inline injection system + activated carbon polishing.

- Result: Reduced H₂S to <5 ppm, extended engine oil change intervals by 40%, reduced unplanned shutdowns to zero.

Case 2: Odor Control at Organic Waste Composting Facility

- Location: Composting plant, Middle East

- Problem: Strong mercaptan odor causing neighborhood complaints and potential regulatory fines.

- Solution: Biofilter system for continuous treatment of exhaust air, combined with pre-wash scrubber for peak loads.

- Result: Odor concentration reduced below detection threshold, facility passed all environmental inspections.

Case 3: Biogas Upgrading Protection in Anaerobic Digester

- Location: Food waste digester, Western Europe

- Problem: H₂S and methyl mercaptan damaging membranes in biomethane upgrading unit.

- Solution: Two-stage treatment: iron-based H₂S removal + impregnated carbon bed for mercaptans.

- Result: Membrane lifespan extended by 2 years, maintenance costs reduced by 35%, biomethane quality fully compliant with grid standards.

OIL SEPARATED WATER TREATMENT TARGETING caseS

H₂S Removal from Produced Water Hydraulic Fracturing Project- Middle East

- Produced water containing 150 ppm H₂S was treated with a non-triazine Thioscav Q56-68 scavenger at a 1:3 dosage ratio.

- The treatment reduced H₂S to 0 ppm without generating solids or scale, delivering water fully compliant for use with drag-reducing agents in fracking operations.

- Result: safe, clean, and reuse-ready water with maintained viscosity and zero operational issues.

H₂S Removal from Produced and Industrial Wastewater – Central Asia

- Wastewater containing 200–1,100 ppm H₂S was treated with a non-aldehyde Thioscav Q56-68 scavenger. At an optimal dosage of 30–40 L/h, hydrogen sulfide was reduced to 0 ppm, with no formation of insoluble deposits.

- The treated water met reinjection quality standards and was compatible with other process chemicals.

- The scavenger maintained full performance in winter conditions down to -25 °C during operation (freezing point -42 °C), delivering consistent results even with reduced contact time.

H₂S Removal from Produced Water – Iraq

- Produced water with an initial 500 ppm H₂S content was treated using an efficient non-aldehyde scavenger.

- The process reduced hydrogen sulfide to below 10 ppm, ensuring compliance with injection water quality requirements.

- The treated water is now safely used for reservoir injection to maintain formation pressure, eliminating corrosion risks and improving operational safety without generating insoluble deposits.

SEWAGE WATER TREATMENT TARGETING caseS

Case 1 – Municipal Wastewater Odor Elimination. Replacement of Sodium Hypochlorite

Location- Middle East

Background

A wastewater facility was treating sewer gas emissions with sodium hypochlorite to control high hydrogen sulfide (H₂S) levels, which frequently reached up to 1,200 ppm. While effective in partial odor reduction, the hypochlorite system had several drawbacks: high chemical consumption, corrosive by-products, safety concerns for operators, and inconsistent H₂S removal during peak loads.

Solution

The facility replaced sodium hypochlorite with the Ecoil non-aldehyde scavenger, designed for selective and rapid H₂S neutralisation without generating corrosive chlorinated by-products. The scavenger was dosed directly into the gas treatment system at controlled rates, ensuring stable performance even during H₂S spikes.

Results:

- H₂S reduction: From 800 ppm up to 1,200 ppm at inlet to <2 ppm at outlet.

- Chemical consumption: Reduced by over 35% compared to sodium hypochlorite.

- Corrosion prevention: No formation of chloride-based corrosion agents, extending equipment life.

- Operational safety: Eliminated risks associated with handling and storing strong oxidisers.

- Environmental compliance: Consistently met local air quality and odor emission standards.

Conclusion

- Switching from sodium hypochlorite to the Ecoil scavenger provided the facility with a more efficient, safer, and environmentally friendly odor control solution, while significantly reducing maintenance and chemical costs.

Case 2: – Sewer Network Corrosion Prevention And Odor Control

Location- Central Asia

Challenge: Corrosion damage to force main pipelines due to high H₂S (>60 ppm) during long retention times.

Solution: Continuous low-dose chemical treatment with a safe, non-triazine scavenger, combined with monitoring sensors.

Result: H₂S levels consistently <5 ppm, significant reduction in maintenance costs, and extended pipe life expectancy.

Frequently Asked Questions

What is the mechanism of action for H₂S scavengers in the oil industry?

H₂S scavengers operate by chemically reacting with hydrogen sulfide, effectively neutralizing its toxic and corrosive properties. In the oil industry, these scavengers are injected into hydrocarbon streams to prevent the formation of H₂S, ensuring safe operations and safeguarding equipment and personnel.

How can I choose the right product for my company's needs?

Selecting the appropriate H₂S scavenger depends on factors such as the concentration of hydrogen sulfide, the composition of the hydrocarbon stream, operating conditions, and regulatory requirements. Please contact us so we can assist you in determining the most suitable product for your specific needs.

What are the benefits of using H₂S scavengers?

Utilizing H₂S scavengers offers several advantages, including enhancing personnel safety by eliminating toxic H₂S gas, protecting equipment from corrosion, reducing maintenance costs, maintaining operational efficiency, and ensuring compliance with safety regulations.

What are the different types of H₂S scavengers available?

There are various types of H₂S scavengers, including liquid scavengers, solid scavengers, and chemical-based scavengers. Each type has its own advantages and is chosen based on factors like application, efficiency, and ease of handling.

Do H₂S scavengers help reduce equipment corrosion and maintenance costs?

Yes, H₂S scavengers effectively neutralize hydrogen sulfide, which helps prevent equipment corrosion caused by H₂S exposure. By minimizing corrosion, they contribute to extending equipment lifespan and reducing maintenance expenses over time.

What is the difference between NGL, LPG, and LNG?

Absolutely, H₂S scavengers can be combined with other chemicals to enhance their effectiveness or tailor them to specific applications. Please contact us so we can help determine the compatibility and synergistic effects of combining different chemicals for optimal results.