ECOIL TECHNOLOGIES

is a specialized provider of advanced solutions and products for the removal of hydrogen sulfide (H₂S) across crude oil & liquids, wells products, produced water, and different types of gases.

H₂S Removal from Crude Oil and LPG

Triazine-Free, Amine-Free Hydrogen Sulfide and Thiols Scavenging Technologies

Transform Your H₂S Treatment with Thioscav Q87-05 ® A Breakthrough in Triazine- and Amine-Free Scavenging

Thioscav Q87-05 ® is an advanced hydrogen sulfide (H₂S) scavenger engineered without triazine or amines. It delivers permanent H₂S removal in crude oil and liquid hydrocarbon streams, enabling compliance with pipeline specifications while enhancing the commercial value of your production.

Compared to conventional solutions such as glyoxal and MEA triazine, Thioscav Q87-05 ® reduces chemical consumption by 50–75%, offering substantial cost savings. Its safer formulation helps protect infrastructure and personnel, and its modular design ensures seamless application from wellhead operations to storage terminals and VLCCs.

Efficient H₂S Removal for Millions of Barrels

With Thioscav Q87-05 ®, millions of barrels of crude oil are treated for H₂S — instantly meeting pipeline requirements and maximizing product value.

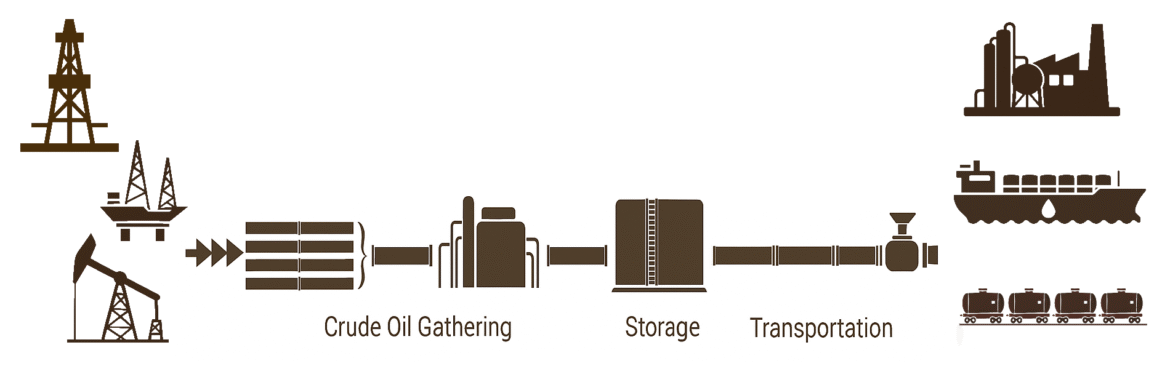

Our reagent can be applied at all stages where hydrogen sulfide are present.

Features

Treatment Workflow

H₂S treatment workflow refers to the step-by-step process used to detect, remove, and control hydrogen sulfide (H₂S) in oil, gas, or produced fluids to meet safety and specification standards.

H₂S treatment workflow refers to the step-by-step process used to detect, remove, and control hydrogen sulfide (H₂S) in oil, gas, or produced fluids to meet safety and specification standards.

STEP 01-

Seamless Integration & Startup Support

Our specialists work closely with your team to understand the unique properties of your crude oil and your commercial requirements.

We develop a tailored Thioscav Q87-05 ® treatment strategy to ensure efficient and reliable H₂S removal.

When needed, we also supply the necessary equipment and provide hands-on- training to get your operations fully aligned with the Thioscav87-05 ® system.

STEP 02 -

Reliable H₂S Removal & Remote Monitoring

Thioscav87-05 ® is continuously dosed into the crude oil stream, delivering consistent and effective H₂S neutralization.

Real-time monitoring of H₂S levels, injection rates, and chemical inventory ensures full operational transparency.

Operators, field personnel, or control room teams can securely access and adjust pump parameters anytime via our encrypted, user-friendly web-based platform.

STEP 03 -

Proven Performance & Operational Efficiency

Thioscav87-05 ® delivers consistent, dependable H₂S removal—ensuring your crude oil meets pipeline specifications with every batch.

While mercaptans can present additional challenges, we offer targeted solutions to address them effectively.

In light of recent geopolitical shifts affecting global crude markets, efficient H₂S treatment is more important than ever for maintaining supply chain reliability and energy security.

Compared to conventional chemistries, Thioscav87-05 ® significantly reduces chemical consumption—resulting in meaningful cost savings.

With rising shipping costs, controlling treatment expenses is critical to staying competitive.

Our fully automated, turnkey system minimizes operational complexity and maximizes process efficiency—helping you extract more value from every barrel.

Frequently Asked Questions

What KIND of scavenger is Thioscav Q87-05 ®?

Thioscav Q87-05 is a non-triazine, non- aldehyde, non-amine, non-glyoxal H₂S and mercaptans removal technology, making it safe and efficient for any steps of oil and gas production.

How is Thioscav Q87-05 ® superior or different compared to MEA-Triazine?

For years, triazine-based treatments have been the standard choice for Producers, Midstream operators, and Refiners. However, many have found that switching to non-triazine alternatives can enhance operational performance and significantly reduce H₂S treatment costs.

So, which solution is better? It ultimately depends on your specific process conditions and application needs.

Are there proven results or examples of effective use of this product?

Yes, we treat millions of barrels of crude oil and condensate every month, successfully reducing H₂S levels to below 10 ppm.

What advantages does Thioscav Q87-05 ® offer when removing H₂S from crude oil?

H₂S removal with Thioscav Q87-05 ® ensures safer operations, improved transportation through pipelines, and better netback prices, increasing the overall value of your barrels.

RELEASED caseS

Eliminating H₂S from Crude Oil in Marine Tankers

- Thioscav Q87-05 ® cuts chemical costs by $10K/month

- 50% fewer deliveries

- Millions of barrels treated — tankers and barges consistently in spec

Crude Oil Truck Terminal H₂S Treatment

- Cut chemical spend by $35K/month using Thioscav Q87-05 ®

- 75% fewer deliveries required

- Reduce chemical usage by up to 80%

Midstream Solutions for Reliable H₂S Removal

- Thioscav Q87-05® enabled the customer to reliably achieve H₂S specifications that prior third-party products failed to meet.

- Total treatment costs were reduced by more than 25%.